Regulation Aspect

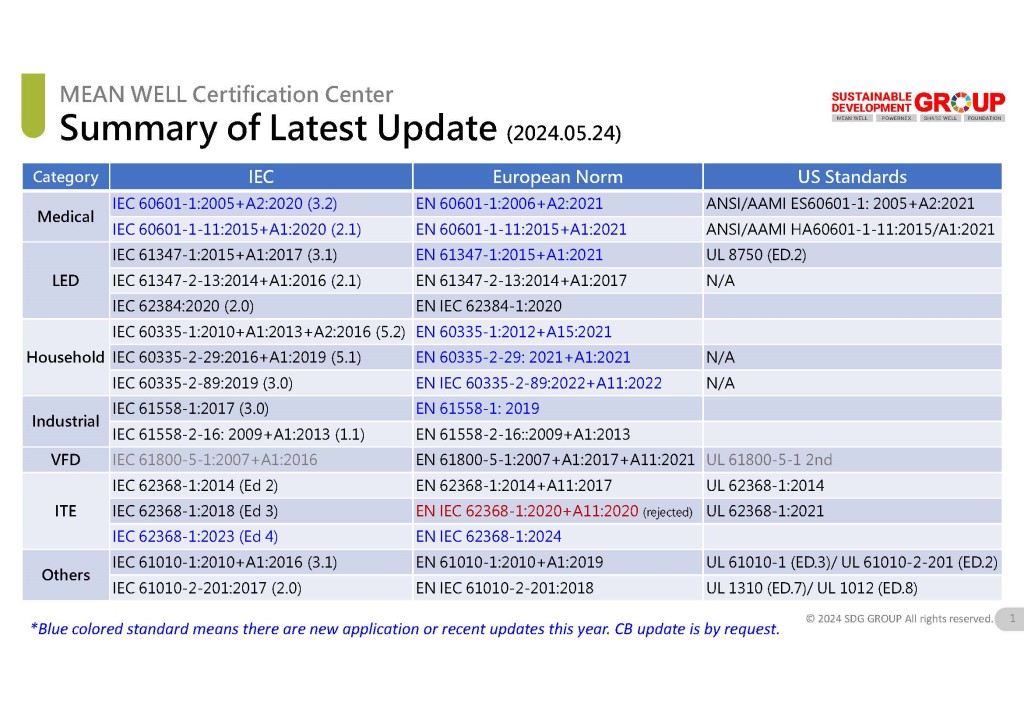

2024 MEAN WELL safety certification version status

62368 ES PS LPS level and 61558 OVC 60335 list for MEAN WELL product

Please refer to the link below .

https://www.meanwell.com/Upload/PDF/62368 ES PS LPS 61558 OVC 60335.pdf

Why the input voltage marked on the spec. sheet is 88~264 VAC while the label on the power supply says that it is 100~240VAC?

During safety verification process, the agency will use a stricter standard ±10% (IEC 62368 uses +10%, -10% for the product with AC input rated) of the input voltage range labeled on the power supply to conduct the test. So, operating at the wider input voltage range as specified on the spec. sheet should be fine. The narrower range of input voltage labeled on the power supply is to fulfill the test standard of safety regulation and make sure that users insert input voltage correctly.

Will MEAN WELL's products with CE marking meet the EMC requirements after assembling into my system?

We cannot guarantee 100% that the final system can still meet the EMC requirements. The location, wiring and grounding of the switching power supply in the system may influence its EMC characteristics. In different environment or applications, the same switching power supply may have different outcomes. Our test results are based on setup shown in the EMC report.

What is ENEC logo? What is the difference between ENEC logo and TUV logo in LED power application?

ENEC is the European safety standard mark.

The scheme is based on the European full certification scheme of ISO-type5, which was initially established in 1991. There are 24 member certification bodies including TUV, VDE, Demko, Nemko participating in the scheme. At the beginning, it was only applicable to all kinds of lamps and lanterns. With the efforts of European industrial and consumer organizations, the scope of application has covered lighting products and their accessories, switches, controllers, connectors, couplers, plugs, consumer electronic products, audio-visual equipment, information technology equipment, household appliances, safety isolation transformers, electrical appliances, filters and other products. ENEC is a more competitive enterprise High value reliable verification mark. The new generation LED power of MEAN WELL have apllied for the ENEC mark presently. The code of verification unit will be added after the ENEC mark. For example,ENEC05 represents the ENEC logo issued by DEKRA, and ENEC17 represents the ENEC logo issued by Nemko. The common ENEC codes are as follows.

| ID | Country | CB Acronym | ID | Country | CB Acronym |

| 02 | Belgium | SGS CEBEC | 15 | Denmark | UL Int DEMKO |

| 05 | Netherlands | DEKRA | 16 | Finland | SGS FIMKO |

| 12 | United Kingdom | BSI | 17 | Norway | NEMKO |

| 14 | Sweden | Intertek Semko | 24 | Germany | TUV Rheinland |

The difference between ENEC and TUV for LED power supply is that ENEC should also meet the requirements of performance EN 62384 in addition to the safety regulations EN 61347-1 and EN 61347-2-13. For example, LED power supply will require that it should be normally burned for 200 hours under TC environment to ensure the suitability of TC declaration.

What is class 2, class II and LPS? What is the difference between class I and class II?

Class I: Equipment where protection against electric shock is achieved by using basic insulation and also providing a means of connecting to the protective earth conductor in the building where by routing those conductive parts that are otherwise capable of assuming hazardous voltages to earth ground if the basic insulation fails. This means a class I SPS will provide a terminal/pin for earth ground connection.

Class II: Equipment in which protection against electric shock does not rely on basic insulation only, but in which additional safety precautions, such as double insulation or reinforced insulation are provided, there being no reliance on either protective earth or installation conditions. This means a class II SPS does NOT have a terminal/pin for earth ground connection.

LPS: When an electronic circuit is powered by a limit power source (LPS), its output current and power are under the limitation shown in IEC 62368-1 Table Q1, and the risk of fire can be reduced significantly. So, the safety distances and flammability rating of components can be much lower. Therefore, the plastic enclosure of these power supplies could use HB flammability rating to reduce cost. This definition comes from ITE/AV product (IEC/EN/UL 62368-1).

Class 2: When an electronic circuit is powered by class 2, its output current and power are under the limitation shown in UL 1310 Table 30.1, and the risk of fire can be reduced significantly. So, the safety distances and flammability rating of components can be much lower. Therefore, the plastic enclosure of these power supplies could use HB flammability rating to reduce cost. This definition comes from UL class 2 power unit (UL 1310).

What are the common safety standards in America and Europe If power supply is used in battery charger?

The common safety standards is UL 62368-1, UL 1012 and UL 1310. UL 1012 and UL 1310 belong to the local national standards of the United States and Canada and are not applicable to other countries. The European market is dominated by EN 61558-1 and EN 61558-2-16.

The status for WEEE and MEAN WELL's approach?

One of the most important changes to the new WEEE Directive 2012/19/EU was the changeover to open scope on 15 August 2018. 2018 therefore represents a turning point: since then, significantly more devices have been subject to compulsory registration than under the old Directive 2002/96/EC. For example, since 15 August 2018, the obligation has also applied to furniture and clothing or textiles with electrical functions.

| device categories | (Recovery) | (Reuse and Recycle) |

|

85 % | 80 % |

|

80 % | 70 % |

|

75 % | 55 % |

|

- |

81 %

|

According to the WEEE regulations, in addition to providing 3R dismantling reports of products, each member country must also establish a complete recycling system for producers to register, and report the statistical results of the Executive Committee on time.

The above products generally refer to END system products. MEAN WELL will continue to provide the 3R dismantling report for the Adaptors and external Battery Chargers for the system vendor to perform the final recovery rate evaluation.

What is LVLE ? If the power supplies can meet LVLE, what is the benefit for the end product?

According from UL8750 definition below:

a. 0-30Vdc output voltage: Maximum 8 amps

b. 30-60Vdc output voltage: 150/V amps

If the power supplies can meet LVLE , the end product does not need the fire enclosure.

What is MOOP and MOPP?

a. MOOP: provide adequate protection to the operator

b. MOPP: provide adequate protection to the patient

c. MOP: only one protection

MW products declare 2xMOPP means that MW product can provide two adequate protections to the patient.

It minimum the risk and also suitable for the patient.

What is the difference between EN 61558-1/EN 61558-2-16. EN 60335-1 and EN 62368-1?

The different requirements are as follow table, this table shall apply the altitude less than 2000m, Pollution Degree 2, OVC II and the rated voltage below 250Vac.

| EN 62368-1 | EN 61558-1 EN 61558-2-16 |

EN 60335-1 | ||

| DC-DC equipment is | YES | NO | YES | |

| Requirement the insulation between SELV and Protective earthing conductor | NO | YES (Basic insulation) | ||

| Limited for earth leakage current | 7.07mApk | 2mArms | 0.75mApk | |

| Requirement for capacitance discharge test | 2 sec < Table 5 of IEC 62368-1 | 1sec < 60V | 1sec < 34V | |

| Requirement for bonding trace | With terminal sizes that are not more than one size smaller than in Table 32 of IEC 62368-1; or with the limited short-circuit test of Annex R; | 40A grounding test shall be performed | 25A grounding test shall be performed and the shall not be less than two bonding traces used | |

| Electric strength test for basin insulation | 2500Vdc | 2100Vac | 1060Vac | |

| Electric strength test for reinforced insulation | 4000Vdc | 4200Vac | 3120Vac | |

| Glow wire test | No need | The test shall be performed | ||

| Minimum distance through insulation for the insulation tape | No require for the distance through insulation but two or more layers are used; | shall be more than 0.15 mm for supplementary insulation shall be more than 3.3 mm for reinforced insulation |

||

| Minimum distance through insulation for the insulation sheet | shall be more than 0,4 mm for supplementary insulation or reinforced insulation | shall be more than 0.5 mm for supplementary insulation and shall be more than 1.0 mm for reinforced insulation | ||

| Bridged Capacitance | One or more bridged Capacitance used | One or more bridged Capacitance used | shall not be less than two bridged Capacitances used | |

| Requirement for the triple wire | Wire with an insulation meeting the requirements of Annex K for use in windings | |||

What is Type HL?

The requirement of Type HL is from UL8750. It provide one option for evaluation of LED drivers that are intended for use in a Class I, Division 2 hazardous location luminaires.

It is simplify the procedure for the manufacture to apply the explosion-proof luminaires.

If the concentration of Hexavalent chromium(Cr6+) exceed > 0.13ug/cm2(IEC-62327-7-1 2015), does it mean that it does not meets RoHs standard?

- according to IEC-62327-7-1 2015, if the test result of Hexavalent chromium (Cr6+) > 0.13ug/cm2, it only stands for the existing of Cr6+, but it doesn't mean it failed the RoHs requirement (<1000 ppm(mg/kg).

- By using ISO3613 is another easy way to evaluate the result. Multiply the thickness of coating and the density of coating (ug/cm2 -> ppm(mg/kg). Ex (Cr6+)2 ug/cm2, thickness of coating: 5um, density of coating :7.14 g • cm−3. The result is 2 ug/cm2 * 5um * 7.14 g • cm−3=71.4 ppm (mg/kg)

- If the result is still not clear, using regulation of 2011/65/EU、2015/863/EU for final evaluation.

Test item (Cr6+) Test method IEC 62321-7-1:2015 Pre-process Boiling water extraction Measuring

equipmentUV-Vis unit ug/cm2 Judgement (1)Using n.d stand for < 0.10ug/cm2以n.d. Meaning no Cr6+ is measured. (2)result from 0.10ug/cm2~0.13ug/cm2, Meaning the result of Cr6+ is unclear. (3)if the result > 0.13ug/cm2, Meaning Cr6+ is presented.